Introduction

Keep using your production equipment by upgrading it at lower cost.

Cemra exchanges your out of date components by a state-of-the-art solution,

without changing the modularity and flexibility of the machine and its stations.

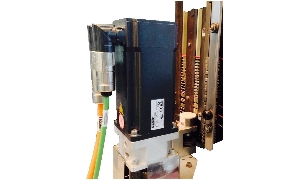

Motors axis upgrade

Old technology, out of date

Loss of reliability, heat sensitivity

Specific solution (design ARA)

Brushless solution

High level technology

Precision, reliability, operating temperature: 0-50° C

Standard solution

Mechanical interface

Replacement is done by keeping as much as possible the current mechanical interface as it is.

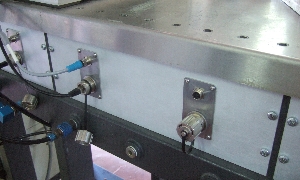

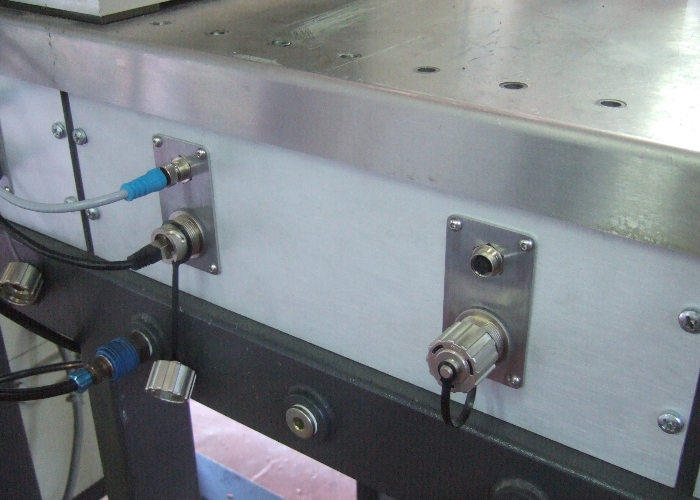

Upgrade of UCDs

Old technology, out of date

Loss of reliability, heat sensitivity

Specific solution (design ARA)

Remote I/O system

State-of-the-art technology EtherCAT

Precision, reliability

Standard industrial solution

Flexibility unchanged

Flexibility and modularity of the machine and its stations are staying unchanged.

Supervisor replacement

Obsoletes components, difficult to exchange (floppy disk drive, hard disk...)

QNX operating system: proprietary, not widely used in industry

Poor backup and recovery medias and tools, no remote support available

Last generation computer

Windows 64 bits system

Many backup and recovery medias and tools: USB key, network disk...

Remote support (using internet connection)

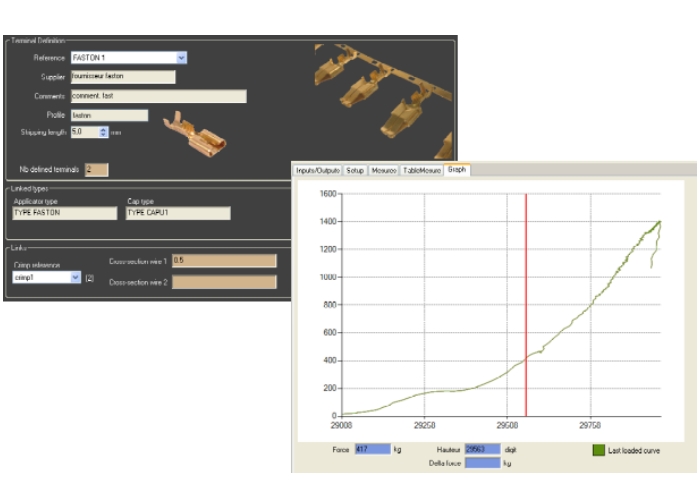

New user interface

Complete redesign of supervisor software, user-friendly, intuitive and visual

Troubleshoot assistance, improved bad crimp detection

New analyzis tools helping the user to easily define and setup crimp parameters